We specialized in the production and sale of Sintered SmCo, can be customized according to various Sintered SmCo, if you need to know more Sintered SmCo relations information, please contact us.

Sintered SmCo

Sintered SmCo is biggest advantage is its high working temperature -350ºC,in general ,magnetizing field of approximately 30 to 45 KOe are required. SmCo magnet is widely used in motors, meters, transducers, instruments, positional detector, generators , wind power generators, radar and other applications.

Detailed Description

Application:

Samarium cobalt magnets usually do not need to be coated, and is widely used in motors, meters, sensors, detectors, engine, radar and other high-tech fields.

|

Material |

Code |

Remanence Br |

Coercivity Force |

Intrinsic Coercivity Force |

Max. Energy Product Bhm |

Curie Temperature |

Max. Operating Temperature | ||||

|

T |

KGs |

KA/m |

KOe |

KA/m |

KOe |

KJ/m3 |

MGOe |

oC |

oC | ||

|

Sintered | |||||||||||

|

SmCo(1:5) |

UNI-18 |

0.75-0.9 |

8.5-9.0 |

620-648 |

7.8-8.2 |

1194-1513 |

15-19 |

127-143 |

16-18 |

750 |

250 |

|

UNI-20 |

0.92-0.96 |

9.2-9.6 |

653-717 |

8.2-9.0 |

1194-1513 |

15-19 |

150-167 |

19-21 |

750 |

250 | |

|

UNI-24 |

0.96-1.0 |

9.6-1.0 |

730-770 |

9.2-9.7 |

1194-1513 |

15-19 |

175-190 |

22-24 |

750 |

250 | |

|

SmCo(2:17) |

UNI-24 |

0.95-1.02 |

9.5-10.2 |

637-732 |

8.0-9.2 |

1433-1990 |

18-25 |

175-190 |

22-24 |

800 |

300 |

|

UNI-26 |

1.02-1.05 |

10.2-10.5 |

748-796 |

9.4-10.0 |

1433-1990 |

18-25 |

195-215 |

24-26 |

800 |

300 | |

|

UNI-28 |

1.05-1.08 |

10.5-10.8 |

756-796 |

9.5-10.0 |

1433-1831 |

18-25 |

205-220 |

26-28 |

800 |

300 | |

|

UNI-28B |

1.02-1.10 |

10.2-11.0 |

420 |

5.2-5.6 |

440-520 |

5.5-6.5 |

205-220 |

26-28 |

800 |

300 | |

|

UNI-30 |

1.08-1.10 |

10.8-11.0 |

780 |

9.8-10.5 |

1433-1831 |

18-25 |

220-240 |

28-30 |

800 |

300 | |

|

UNI-30B |

1.08-1.15 |

10.8-11.5 |

420 |

5.2-5.6 |

440-520 |

5.5-6.5 |

220-240 |

28-30 |

800 |

300 | |

|

Bonded | |||||||||||

|

SmCo(1:5) |

UNI-6 |

0.4 |

4.0 |

280 |

3.5 |

800 |

10 |

30-50 |

4-6 |

- |

120 |

|

UNI-10 |

0.5 |

5.0 |

320 |

4.0 |

800 |

10 |

50-65 |

6-8 |

- |

120 | |

|

SmCo(2:17) |

UNI-10 |

0.6 |

6.0 |

360 |

4.5 |

800 |

10 |

65-80 |

8-10 |

- |

120 |

|

UNI-12 |

0.7 |

7.0 |

400 |

5.0 |

800 |

10 |

80-95 |

10-12 |

- |

120 | |

|

SmCo5 |

Sm2Co17 | |

| Temp. Coeff. Of Br:1%/oC |

-0.05 |

-0.03 |

| Temp.Coeff. Of iHc: %/oC |

-0.3 |

-0.2 |

| Curie Temperature: oC |

700-750 |

800-850 |

| Density: g/cm3 |

8.2-8.4 |

8.3-8.5 |

| Vickers Hardness: Hv |

450-500 |

500-600 |

| Working Temperature : oC |

250 |

300 |

|

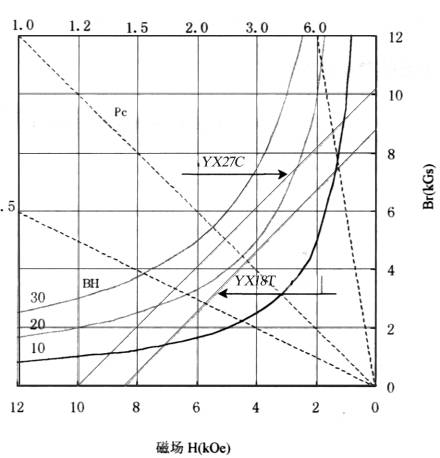

Typical Characteristic Curve for SmCo permanent magnet |

|

|

Related Products

what is the Sintered SmCo?

Sintered SmCo is processed by special technology particular SmCo powder mixture made of resin material to suppress heating. This special shape made of parts, and can be made as small as mold tolerance, need to follow-up machining. Its magnetic properties is lower than the sintering, giving designers an extremely high magnetic properties, outstanding thermal stability and excellent corrosion resistance in one of the high-performance magnet.

Sintered SmCo is processed by special technology particular SmCo powder mixture made of resin material to suppress heating. This special shape made of parts, and can be made as small as mold tolerance, need to follow-up machining. Its magnetic properties is lower than the sintering, giving designers an extremely high magnetic properties, outstanding thermal stability and excellent corrosion resistance in one of the high-performance magnet.

Sintered SmCo applications

Sintered SmCo materials with high magnetic properties and good corrosion resistance. Use servo motor, magnetic drive pumps and sensors, particularly those that require high temperature magnets, too wide temperature range, or to work in the corrosive environment.

Sintered SmCo materials with high magnetic properties and good corrosion resistance. Use servo motor, magnetic drive pumps and sensors, particularly those that require high temperature magnets, too wide temperature range, or to work in the corrosive environment.