| General Introduction

Sintered Ferrite magnet (Ceramic Magnets, Hard Ferrite Magnet) were developed in the 1960's as a low cost alternative to metallic magnets. Even though they exhibit low energy (compared with other permanent magnet materials) and are relatively brittle and hard, Sintered Ferrite magnet (ceramic magnets, Hard ferrite magnet) have won wide acceptance due to their good resistance to demagnetization, excellent corrosion resistance and low price per pound. In fact, measured by weight, ferrite represents more than 75 percent of the world magnet consumption. Sintered Ferrite Magnet (Hard Ferrite Magnet) is the first choice for most types of DC motors, magnetic separators, magnetic resonance imaging and automotive sensors. The elements of Sintered NdFeB Magnet (Hard Ferrite magnet) are ferric oxide/barium, strontium. Ferrite has higher coercive force and higher resistance to be demagnetized and oxidized than other non-rare earth permanent magnets. The biggest advantage of such magnet is their low cost. It is widely used from motors and loudspeakers to toys and craft, industrial holding magnet etc. Besides industrial application, Sintered Ferrite magnet (Ceramic Magnets, Hard Ferrite Magnet) are widely use in Educational area. |

|

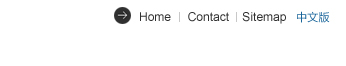

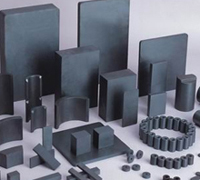

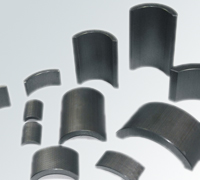

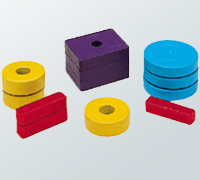

| What shapes can it be formed? | ceramic magnet, sintered ferrite magnet |

|

|

|

|

|

|

Magnetic Properties of Sintered Ferrite Magnets

National standard

Grade |

Value |

|||||||

Br |

Hcb(BHC) |

Hcj(IHC) |

(BH)max |

|||||

mT |

KG |

KA/m |

KOe |

KA/m |

KOe |

Kj/m3 |

MGOe |

|

Y10T(=C1) |

200/218 |

2.00/2.18 |

125/145 |

1.57/1.82 |

210/250 |

2.64/3.14 |

6.5/8.0 |

0.8/1.0 |

Y25 |

360/370 |

3.60/3.70 |

135/150 |

1.70/1.88 |

140/170 |

1.76/2.14 |

22.5/25.3 |

2.8/3.2 |

Y30(=C5) |

380/385 |

3.80/3.85 |

191/210 |

2.40/2.64 |

199/220 |

2.50/2.51 |

26.0/28 |

3.4/3.7 |

Y30BH |

380/390 |

3.80/3.90 |

223/235 |

2.80/2.95 |

231/245 |

2.90/3.08 |

27.0/30.0 |

3.4/3.7 |

Y33 |

410/420 |

4.10/4.20 |

220/235 |

2.77/2.95 |

225/240 |

2.83/3.01 |

31.5/33.0 |

4.0/4.2 |

Y35 |

400/410 |

4.00/4.10 |

175/195 |

2.20/2.45 |

180/200 |

2.26/2.51 |

30.0/32.0 |

3.8/4.0 |

C8(=C8A) |

385/390 |

3.85/3.90 |

235/255 |

2.95/3.20 |

242/265 |

3.05/3.33 |

27.8/30.0 |

3.5/3.7 |

C10 |

400/410 |

4.00/4.10 |

288/300 |

3.62/3.77 |

280/287 |

3.51/3.60 |

30.4/31.9 |

3.8/4.0 |

Chinese standard

Material |

Br |

HcB |

HcJ |

(BH)max |

||||

mT |

KG |

KA/m |

Oe |

KA/m |

Oe |

Kj/m3 |

MGOe |

|

Y8T |

200~235 |

≥2000 |

125~160 |

≥1570 |

210~280 |

≥2610 |

6.5~9.5 |

≥0.8 |

Y22H |

310~360 |

≥3100 |

220~250 |

≥2770 |

280~320 |

≥3520 |

20.0~24.0 |

≥2.5 |

Y25 |

360~400 |

≥3600 |

135~170 |

≥1700 |

140~200 |

≥1760 |

22.5~28.0 |

≥2.8 |

Y26H-1 |

360~390 |

≥3600 |

220~250 |

≥2512 |

225~255 |

≥2830 |

23.0~28.0 |

≥2.9 |

Y26H-2 |

360-380 |

≥3600 |

263-288 |

≥3300 |

318-350 |

≥4000 |

24.0-28.0 |

≥3.0 |

Y27H |

370~400 |

≥3500 |

225-240 |

≥2830 |

235-260 |

≥2950 |

25.0~29.0 |

≥3.1 |

Y28 |

370-400 |

≥3700 |

175-210 |

≥2200 |

180-220 |

≥2260 |

26.0-30.0 |

≥3.3 |

Y28H-1 |

380-400 |

≥3800 |

240-260 |

≥3020 |

250-280 |

≥3140 |

27.0-30.0 |

≥3.1 |

Y28H-2 |

360-380 |

≥3600 |

271-295 |

≥3400 |

382-405 |

≥1800 |

26.0-30.0 |

≥3.3 |

Y30 |

370~400 |

3.7~4.0 |

175~210 |

2.20~2.64 |

180~220 |

2.26~2.77 |

26.0~30.0 |

3.3~3.8 |

Y30H-1 |

380~400 |

≥3800 |

230-275 |

≥2890 |

235-290 |

≥2950 |

27.0~32.5 |

≥3.4 |

Y30H-2 |

395-415 |

≥3950 |

275-300 |

≥3460 |

310-335 |

≥3900 |

27.0~32.0 |

≥3.4 |

Y32 |

400~420 |

≥4000 |

160~190 |

≥2010 |

165~195 |

≥2070 |

30.0~33.5 |

≥3.8 |

Y32H-1 |

400-420 |

≥4000 |

190-230 |

≥2390 |

230-250 |

≥2890 |

34.5-35.0 |

≥4.0 |

Y32H-2 |

400-440 |

≥4000 |

224-240 |

≥2810 |

230-250 |

≥2890 |

31.0-34.0 |

≥3.9 |

Y33 |

410~430 |

≥4100 |

220~250 |

≥2760 |

225~255 |

≥2830 |

31.5~35.0 |

≥4.0 |

Y33H |

410-430 |

≥4100 |

250-270 |

≥3140 |

250-275 |

≥3140 |

31.5-35.0 |

≥4.0 |

Y34 |

420-440 |

≥4200 |

200-230 |

≥2510 |

205-235 |

≥2580 |

32.5-36.0 |

≥4.1 |

Y35 |

430-450 |

≥4300 |

215-239 |

≥2700 |

217-242 |

≥2730 |

33.1-33.2 |

≥4.2 |

Y36 |

440-450 |

≥4400 |

247-271 |

≥3100 |

250-374 |

≥4400 |

35.1-38.3 |

≥4.4 |

Y38 |

440-460 |

≥4400 |

285-305 |

≥3580 |

294-310 |

≥3690 |

36.6-40.6 |

≥4.6 |

Y40 |

450-460 |

≥4500 |

330-354 |

≥4150 |

340-360 |

≥4270 |

37.6-41.8 |

≥4.7 |

USA standard

Material |

Br |

HcB |

HcJ |

(BH)max |

||||

mT |

KG |

KA/m |

KOe |

KA/e |

KOe |

kj/m3 |

MGOe |

|

C1 |

230 |

2.3 |

148 |

1.86 |

258 |

3.5 |

8.36 |

1.05 |

C5 |

380 |

3.8 |

191 |

2.4 |

199 |

2.5 |

27 |

3.4 |

C7 |

340 |

3.4 |

258 |

3.23 |

318 |

4.00 |

21.9 |

2.75 |

C8(=C8A) |

385 |

3.85 |

235 |

2.95 |

242 |

3.05 |

27.8 |

3.5 |

C8B |

420 |

4.2 |

232 |

2.913 |

236 |

2.96 |

32.8 |

4.12 |

C9 |

380 |

3.8 |

280 |

3.516 |

320 |

4.01 |

26.4 |

3.32 |

C10 |

400 |

4.0 |

288 |

3.617 |

280 |

3.51 |

30.4 |

3.82 |

C11 |

430 |

4.3 |

200 |

2.512 |

204 |

2.56 |

34.4 |

4.32 |

Europe standard

The standard from International Electronics Committee(IEC404-8-1)

Grade |

Allowed Value (min/typical) |

|||||||

Br |

Hcb(BHC) |

Hcj(IHC) |

(BH)max |

|||||

MT |

KG |

KA/m |

KOe |

KA/m |

KOe |

Kj/m3 |

MGOe |

|

HF8/22 |

200/220 |

2.00/2.20 |

125/140 |

1.57/1.76 |

220/230 |

2.76/2.89 |

6.5/6.8 |

0.8/1.1 |

HF20/19 |

320/333 |

3.20/3.33 |

170/190 |

2.14/2.39 |

190/200 |

2.39/2.51 |

20.0/21.0 |

2.5/2.7 |

HF20/28 |

310/325 |

3.10/3.25 |

220/230 |

2.76/2.89 |

280/290 |

3.52/3.64 |

20.0/21.0 |

2.5/2.7 |

HF22/30 |

350/365 |

3.50/3.65 |

255/265 |

3.20/3.33 |

290/300 |

3.64/3.77 |

22.0/23.5 |

2.8/3.0 |

HF24/16 |

350/365 |

3.50/3.65 |

155/175 |

1.95/2.20 |

160/180 |

2.01/2.26 |

24.0/25.5 |

3.0/3.2 |

HF24/23 |

350/365 |

3.50/3.65 |

220/230 |

2.76/2.89 |

230/240 |

2.89/3.01 |

24.0/25.5 |

3.0/3.2 |

HF24/35 |

360/370 |

3.60/3.70 |

260/270 |

3.27/3.39 |

350/360 |

4.40/4.52 |

24.0/25.5 |

3.0/3.2 |

HF26/16 |

370/380 |

3.70/3.80 |

155/175 |

1.95/2.20 |

160/180 |

2.01/2.26 |

26.0/27.0 |

3.2/3.4 |

HF26/18 |

370/380 |

3.70/3.80 |

175/190 |

2.20/2.39 |

180/190 |

2.26/2.39 |

26.0/27.0 |

3.3/3.4 |

HF26/24 |

370/380 |

3.70/3.80 |

230/240 |

2.89/3.01 |

240/250 |

3.01/3.14 |

26.0/27.0 |

3.3/3.4 |

HF26/26 |

370/380 |

3.70/3.80 |

230/240 |

2.89/3.01 |

260/270 |

3.27/3.39 |

26.0/27.0 |

3.3/3.4 |

HF26/30 |

385/395 |

3.85/3.95 |

260/270 |

3.27/3.39 |

300/310 |

3.77/3.89 |

26.0/27.0 |

3.3/3.4 |

HF28/26 |

385/395 |

3.85/3.95 |

250/265 |

3.14/3.33 |

260/275 |

3.27/3.45 |

28.0/30.0 |

3.5/3.8 |

HF28/28 |

385/395 |

3.85/3.95 |

260/270 |

3.27/3.39 |

280/290 |

3.50/3.60 |

28.0/30.0 |

3.5/3.8 |

HF30/26 |

395/405 |

3.95/4.05 |

250/260 |

3.14/3.33 |

260/270 |

3.27/3.39 |

30.0/31.5 |

3.8/3.9 |

HF32/17 |

410/420 |

4.10/4.20 |

160/180 |

2.01/2.26 |

165/175 |

2.07/2.20 |

32.0/33.0 |

4.0/4.1 |

HF32/22 |

410/420 |

4.10/4.20 |

215/225 |

2.70/2.83 |

220/230 |

2.76/2.89 |

32.0/33.0 |

4.0/4.1 |

HF32/25 |

410/420 |

4.10/4.20 |

240/250 |

3.01/3.14 |

250/260 |

3.14/3.27 |

32.0/33.0 |

4.0/4.1 |

Japan TDK standard

Grade |

Composition |

Br |

Hcb |

Hcj |

BH max |

||||

mT |

kG |

kA/m |

kOe |

kA/m |

kOe |

KJ/m3 |

MGOe |

||

FB40 |

SrO6Fe2O3 |

410+/-10 |

4.1+/-10 |

234.8+/-11.9 |

2.95+/-0.15 |

238.7+/-15.9 |

3.0+/-0.2 |

31.4+/-1.6 |

3.95+/-0.2 |

FB3N |

SrO6Fe2O3 |

395+/-15 |

3.95+/-15 |

234.8+/-11.9 |

2.95+/-0.15 |

238.7+/-15.9 |

3.0+/-0.2 |

28.7+/-2.4 |

3.6+/-0.3 |

FB3G |

SrO6Fe2O3 |

375+/-15 |

3.75+/-15 |

254.6+/-15.9 |

3.2+/-0.2 |

270.6+/-19.9 |

3.4+/-0.25 |

25.9+/-2.4 |

3.25+/-0.3 |

FB3X |

SrO6Fe2O3 |

375+/-15 |

3.75+/-15 |

234.8+/-11.9 |

2.95+/-0.15 |

238.7+/-15.9 |

3.0+/-0.2 |

25.9+/-2.4 |

3.25+/-0.3 |

FB1A |

SrO6Fe2O3 |

220+/-15 |

2.20+/-15 |

159.2+/-15.9 |

2.0+/-0.2 |

258.6+/-19.9 |

3.25+/-0.25 |

8.9+/-1.6 |

1.1+/-0.2 |

FB5H |

SrO6Fe2O3 |

405+/-15 |

4.05+/-15 |

298.4+/-11.9 |

3.75+/-0.15 |

322.3+/-11.9 |

4.05+/-0.15 |

31.1+/-1.6 |

3.9+/-0.2 |

FB4X |

SrO6Fe2O3 |

420+/-10 |

4.20+/-10 |

234.8+/-11.9 |

2.95+/-0.15 |

238.7+/-15.9 |

3.0+/-0.2 |

33.4+/-1.6 |

4.2+/-0.2 |

FB4B |

SrO6Fe2O3 |

400+/-10 |

4.00+/-10 |

254.6+/-11.9 |

3.2+/-0.2 |

262.6+/-19.9 |

3.3+/-0.25 |

30.3+/-1.6 |

3.8+/-0.2 |

FB4A |

SrO/ BaO6Fe2O3 |

410+/-10 |

4.10+/-10 |

175.1+/-15.9 |

2.2+/-0.2 |

176.7+/-15.9 |

2.22+/-0.2 |

31.8+/-1.6 |

4.0+/-0.2 |

FBGN |

SrO6Fe2O3 |

440+/-10 |

4.40+/-10 |

258.6+/-11.9 |

3.25+/-0.15 |

262.6+/-11.9 |

3.3+/-0.15 |

36.7+/-1.6 |

4.6+/-0.2 |

FB6B |

SrO6Fe2O3 |

420+/-10 |

4.20+/-10 |

302.4+/-11.9 |

3.8+/-0.15 |

318.3+/-11.9 |

4.0+/-0.15 |

33.4+/-1.6 |

4.2+/-0.2 |

FB6H |

SrO6Fe2O3 |

400+/-10 |

4.00+/-10 |

302.4+/-11.9 |

3.8+/-0.15 |

358.1+/-11.9 |

4.5+/-0.15 |

30.3+/-1.6 |

3.8+/-0.2 |

FB6E |

SrO6Fe2O3 |

380+/-10 |

3.80+/-10 |

290.5+/-11.9 |

3.65+/-0.15 |

393.9+/-11.9 |

4.95+/-0.15 |

27.5+/-1.6 |

3.45+/-0.2 |

FB5N |

SrO6Fe2O3 |

440+/-10 |

4.40+/-10 |

256.8+/-11.9 |

2.85+/-0.15 |

2259.2+/-11.9 |

2.88+/-0.15 |

36.7+/-1.6 |

4.6+/-0.2 |

FB5B |

SrO6Fe2O3 |

420+/-10 |

4.20+/-10 |

262.6+/-11.9 |

3.3+/-0.15 |

266.6+/-11.9 |

3.35+/-0.15 |

33.4+/-1.6 |

4.2+/-0.2 |

Physical Characteristics

Compressive Strength |

1.4 x 104 kg/cm2 |

Required Magnetizing Field |

12,000 - 15,000 Oe |

Electrical Resistivity |

> 104 μ-ohm-cm/cm2 |

Density |

4.7-5.0 g/cm3 |

Recoil Permeability |

1.05 μr |

Rev. Temp. Coeff. |

-0.20 %/°C |