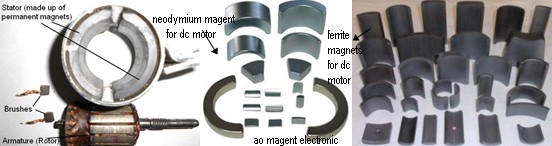

In the design of permanent magnet DC motor, dc motor magnet shapes and sizes, including commutation performance has a very important effect on motor performance. Select the appropriate shapes and sizes of permanent magnet for DC motor are important. Tile-shaped magnetic pole structure is one common pole permanent magnet DC motor structure. Field road use a combination of methods, by Ansys software, compare and analyze the effects of different shapes and sizes of tile-shaped magnetic poles of the permanent magnet DC motor performance, and through prototype testing to verify the correctness of the analysis results, and finally get the permanent magnets of different shapes Features conclusions. Conclusion permanent magnet motor design has some significance. Pole permanent magnet DC motor structure for a variety of types, commonly used with Arc magnets for DC Motor(arc ferrite magnets for dc motor and arc neodymium magnets for dc motor), cylinder magnet for dc motor, curved magnets for dc motor and Rectangle magnet for dc motor.

Motor magnets and Rotor magnets are most in Arc or segment shape.some are Block magnets. Arc Magnets is one special shape of Rare earth magnets. It is always manufactured via Wire Cutting and grinding etc .Regular Arc magnets or Segment magnets have the following important factors such as ,Outer Diameter Or Outer Radius,Inner Diameter or Inner Radius ,Degree of Angle,Thickness,Length ,Round Edge etc . AO Magnet Electronic, following ISO/TS16949:2002, Iso9001:2008 RoHs standards, have been supplying magnets for DC motor with best qualtiy & competitive price for years.

| Magnets | Br(T) | Hci(kA/m) | (BH)max(kJ/m3) | Tc(C) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Nd2Fe14B(sintered) | 1.0C1.4 | 750C2000 | 200C440 | 310C400 | ||||||

| Nd2Fe14B(bonded) | 0.6C0.7 | 600C1200 | 60C100 | 310C400 | ||||||

| SmCo5(sintered) | 0.8C1.1 | 600C2000 | 120C200 | 720 | ||||||

| Sm(Co,Fe,Cu,Zr)7(sintered) | 0.9C1.15 | 450C1300 | 150C240 | 800 | ||||||

| Alnico (sintered) | 0.6C1.4 | 275 | 10C88 | 700C860 | ||||||

| Sr-ferrite (sintered) | 0.2C0.4 | 100C300 | 10C40 | 450 | ||||||

| Total | 6 arc segment magnets neodymium, SmCo, ferrite | |||||||||

| Material | Reversible Losses °C | Working Temperature °C | Curie Temperature °C | Sub Zero Affects | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Ferrite | 0.19% | 250 | 460 | Large irreversible losses below -40 °C | ||||||

| ALNICO | 0.02% | 550 | 860 | Losses < 10% down to 4K | ||||||

| SmCo | 0.03% | 300 | 750 | Minimal loses down to 4 K | ||||||

| NdFeB | 0.12% | 120 | 320 | No losses down to 77 K | ||||||

| Total | 6 arc segment magnets neodymium, SmCo, ferrite | |||||||||